Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SAE J525

Brand: Huijie

Usage: Special Purpose

Type: Welded

Technique: Cold Drawn

Material: Low-carbon Steel SAE1010,SAE1015

Surface Treatment: Other

Section Shape: Round

Size Range: OD:6-168mm Wt:0.8-10mm

Delivery Condition: Cold Drawn And Annealed

Application:: Hydraulic Fluid Line Tubes,pressure Tube

Heat-treatment: Cold Drawing And Annealed

Products Methods: Welded,Cold Drawn Over Mandrel

Standard: SAE J-525B Welded Hydraulic Steel Tube

Packaging: Bundles Package, Wooden Box

Productivity: 7000 tons/month

Transportation: Ocean

Place of Origin: Zhejiang, China

Supply Ability: 3000 tons/month

Certificate: ISO9001-2008, TS16949

HS Code: 73043190

Port: Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,CFR,CIF,FCA

SAE J525 welded hydraulic tubing for hydraulic fluid lines,pressure tubing for Automotive Steel Tubes

SAE J525 Metallic round tubing,Low-Carbon steel tubing,Carbon Steel Tubes for surface vehicle

GENERAL

This specification covers cold worked and annealed electric resistance welded low carbon steel pressure tubing

with outside diameter 3/8 inch to 2-1/2 inch, inclusive, for use as hydraulic lines for industrial equipment or other

applications requiring flaring and bending.

CHEMICAL COMPOSITION (percentage by weight)

| Carbon | 0.18 maximum |

| Manganese | 0.30 – 0.60 |

| Phosphorus | 0.040 maximum |

| Sulphur | 0.050 maximum |

The tubing shall conform to the following requirements:

| Tensile Strength | 45,000 psi minimum |

| Yield | 25,000 minimum |

| Elongation in 2 inch | 35 percent* minimum |

| Rockwell Hardness | B65 maximum |

*For tubes with OD of 3/8 inch and/or wall thickness of 0.035, a minimum elongation of 30 percent is permitted.

FLATTENING TEST — A section at least three inches in length shall be taken from every 1500 feet or less of finished

tubing and shall be flattened between parallel plates to three times the wall thickness of the tube. The weld shall be placed

at a point of 90 degrees from the direction of applied force. Any cracking or flaws revealed by this test shall be cause

for rejection. Superficial ruptures resulting from minor surface imperfections shall not be cause for rejection.

REVERSE FLATTENING TEST — A section at least four inches in length shall be taken from every 1500 feet or less

of finished tubing and split longitudinally 90 degrees on each side of the weld and the sample opened and flattened.

There shall be no evidence of cracks or lack of penetration or overlaps resulting from flash removal in the weld.

WELDED HYDRAULIC TUBING/DOM Steel Tubing/STEEL TUBING

EXPANSION TEST — A suitable specimen shall be taken from each 1500 feet or less of tubing and subjected to an expansion

over a plug. The outside diameter must be expanded 25 percent throughout a length equal to the outside diameter of the tubing

or one inch, whichever is greater. There shall be no evidence of cracking in this test.

PRESSURE OR ELECtrICAL TEST — Tubing supplied under this specification shall have been hydrostatically tested at a fiber

stress of 20,000 psi or at an actual pressure of 5,000 psi, whichever is less, based on the applicable minimum wall, or tested

by use of a nondestructive electrical test approved by purchaser.

DIMENSIONS

When tubing is specified by outside diameter and inside diameter, the tolerances shown in the table shall apply.

| Nominal Outside Diameter, Inches | OD inches | ID inches |

| 3/8 | ±0.002 | ±0.005 |

| Over 3/8 to 5/8 inclusive | ±0.0025 | ±0.0025 |

| Over 5/8 to 2 inclusive | ±0.003 | ±0.003 |

| Over 2 to 2-1/2 inclusive | ±0.004 | ±0.004 |

When tubing is specified by the outside diameter (or the inside diameter) and the nominal wall thickness, the tolerances for the

specified diameter shall apply and the wall thickness shall not vary more than plus or minus 10 percent.

QUALITY CONTROL of NEW-ERA STEEL TUBE

MANUFACTURE — The tubing shall be normalized and followed by a cold working operation. The cold working shall result in

minimum reduction of areas of 15 percent of which at least 8 percent shall be reduction of wall thickness. After cold working,

the tubing shall be annealed in such a manner that the resultant product will meet all requirements of this specification.

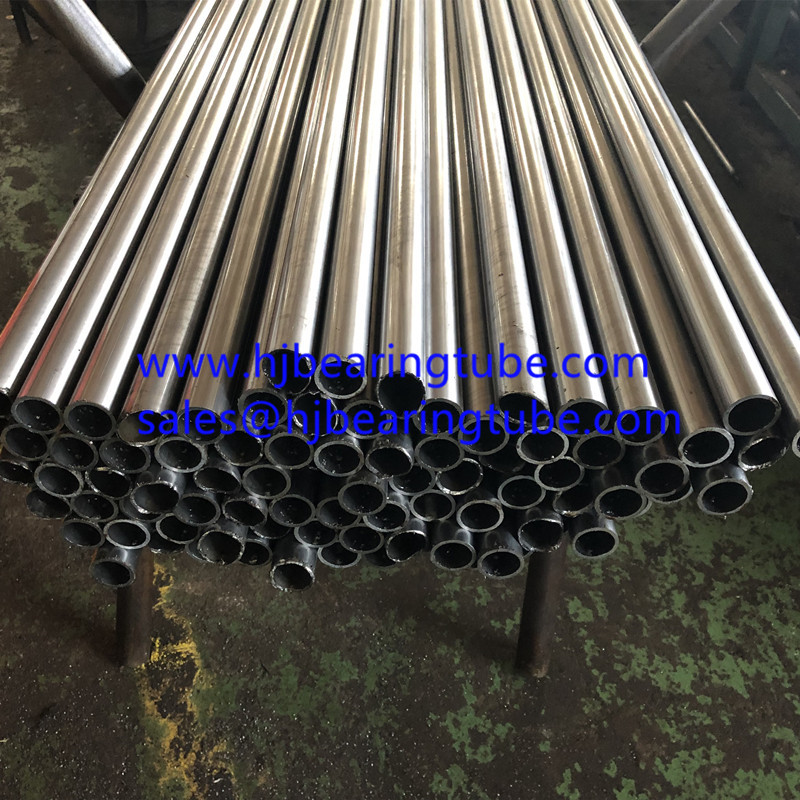

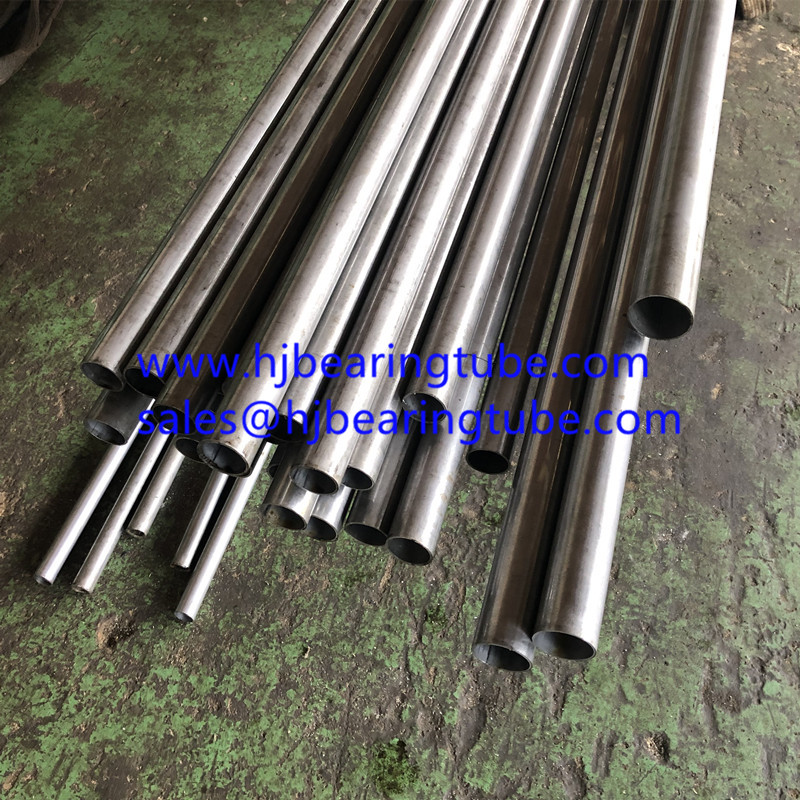

product pictures:

Metallic tubing,carbon tubing,welded hydraulic tubing,hydraulic fluid line tubing,steel tube,steel tubing

welded hydraulic tubing,SAE J525 round tubing,J525 metallic tubing,automotive steel tubes

Product Categories : Automotive Steel Tubes

Home > Products > Automotive Steel Tubes > SAEJ525 welded hydraulic tubing DOM round tubing

Send Inquiry

Mr. Kevin

Tel:86-0574-87491308

Fax:86-0574-87491848

Mobile Phone:+8613355844917

Email:sales@hjbearingtube.com

Address:Industrial Park, Zhangting Town,Yuyao City, Ningbo, Zhejiang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.