Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SAE J524

Brand: Huijie

Usage: Special Purpose

Type: Seamless

Technique: Cold Drawn

Material: Low Carbon Steel SAE1010,St35.8 St37.4

Surface Treatment: Other

Section Shape: Round

Size Range: OD:6-329mm Wt:6-100mm

Delivery Condition: Cold Finished And Annealed

Application:: Hydraulic Fluid Lines Tubing

Heat-treatment: Cold Drawing/Cold Rolling/Cold Finished

Products Methods: Seamless Cold Finished Steel Pipes

Standard: SAE J524 AMS 5050 E

Packaging: Bundles Package, Wooden Box

Productivity: 3000 tons/month

Transportation: Ocean

Place of Origin: Zhejiang, China

Supply Ability: 3000 tons/month

Certificate: ISO9001-2008, TS16949

HS Code: 73043190

Port: Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,CFR,CIF,FCA

SAE J524 cold drawn and annealed seamless low-carbon steel pressure tubing intended for use as

hydraulic lines and in other applications requiring tubing a quality suitable for flaring and bending.

SAE J524 Cold Drawn Seamless Pipes,hydraulic fluid lines pipes,hydraulic pressure tubing.

The the cold finished Steel Tubes mainly for hydraulic steel tubing and cold drawn pressure tubing

SCOPE

This specification covers cold drawn and annealed seamless low carbon steel pressure tubing for use as hydraulic lines.

HYDROSTATIC TEST

Tubing supplied under this specification shall have been tested at not less than 1,000 lbs. hydrostatic pressure or higher

in case working conditions require.

CLEANLINESS

It is desired that the inside of tubing shall be bright, clean, and free from grease, drawing compounds, oxide, scale,

carbon deposits, and any contamination that cannot be readily removed by cleaning with alkaline cleaners or benzine.

CORROSION PROTECTION OF INTERIOR OF TUBES

The inside of the tubing having open ends shall be protected by a coating of clean oil to protect the interior of the tubing against

corrosion during shipment and normal storage periods.The corrosion preventive oil used shall be such that, after extended storage

periods, it can readily be removed with an alkaline cleaning solution or with benzine (Standard Solvent).

QUALITY

Tubing shall be free from defects and in accordance with the best commercial practice.

CHEMICAL COMPOSITION (percentage by weight)

The tubing shall conform to the following chemical analysis:

| Carbon……………0.18 max. | Phosphorus……….0.040 max. |

| Manganese……..0.30 -0.60 | Sulphur…………….0.050 max. |

Seamless low carbon steel tubing annealed for bending — Pressure type.

PHYSICAL PROPERTIES

The tubing shall conform to the following physical requirements

Tensile strength Lb/Sq. inch, minimum………………..45,000

Elongation in 2 inches, minimum………………………..35 percent*

For tubes with an OD of 3/8 inch and less and wall thickness of 0.035 inch and less, a minimum elongation of 30 percent is permitted.

SEAMLESS HYDRAULIC TUBING

A three inch section cut from the tubing shall not crack or show any flaws when flattened between parallel plates to three times the

wall thickness of the tube.

A section of tube approximately four inches in length with the ends burred shall withstand being expanded at one end over a polished

tapered mandrel having an included angle of 60 degrees until the actual average inside diameter is increased 30 percent.

The expansion test shall be made in a die in order to restrict the expansion of 30 percent. The axis of the mandrel should be paralled

to the axis of the tube during the expansion tests.

VARIATIONS

The diameter of the tubing shall not vary from that specified more than the following amounts:

| OD Sizes inches | Outside Diameter, In. | |

| Plus | Minus | |

| Below 3-1/2 to 1-1/2 Incl. | 0.010 | 0.010 |

| Below 1-1/2 to 1/2 ID Incl. | 0.005 | 0.005 |

| Below 1/2 ID | 0.003 | 0.003 |

When the outside diameter and wall thickness of 1/2 inch to 3-1/2 inch OD tubes are specified, the outside diameter shall conform to

the tolerances given in the above table, and the wall thicknesses shall not vary from that specified more than plus or minus 10 percent.

When less than 1/2 inch ID, the outside diameter shall conform to the tolerances given in the above table. The wall thickness shall not

vary from that specified more than plus or minus 15 percent.

PICKLE BRITTLENESS

Tubing which is pickled to remove scale shall be treated to eliminate pickle brittleness.

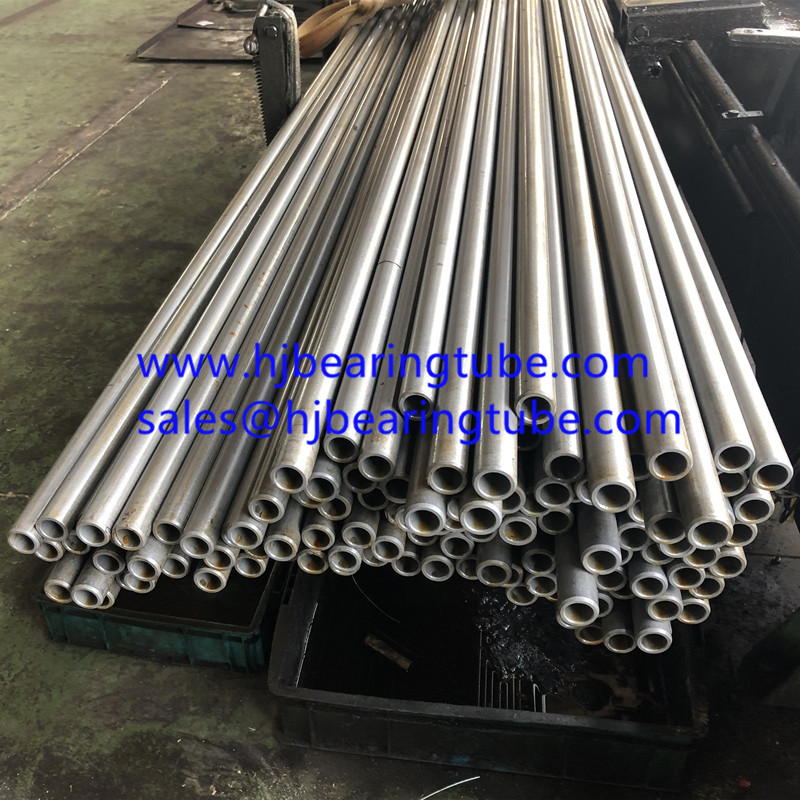

Products Pictures:

Tags:seamless hydraulic tubing,SAE J524 seamless tubing,cold drawn hydraulic tubing,cold drawn

pressure tubing,SAE J524 steel tubing,Low-Carbon Steel Tubes.Low carbon steel tubing,J524 round

tubing,J524 metal tubing,SAE J524 seamless tubing,seamless hydraulic tubing,cold drawn pipes

Product Categories : Cold Drawn Seamless Pipes

Home > Products > Cold Drawn Seamless Pipes > SAEJ524 seamless hydraulic tubing cold drawn pipes

Send Inquiry

Mr. Kevin

Tel:86-0574-87491308

Fax:86-0574-87491848

Mobile Phone:+8613355844917

Email:sales@hjbearingtube.com

Address:Industrial Park, Zhangting Town,Yuyao City, Ningbo, Zhejiang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.